The innovative circular technologies of URBIOFIN project for municipal waste management are ready to be implemented Europe-wide

The majority of the municipal biowaste generated in Europe is managed by landfilling and incineration thus missing out on its valorisation potential.

In coherence with the EU legislation, the organic fraction of municipal waste should be treated using novel treatment methods based on green technologies, and the potential to be further valorised to bio-based products.

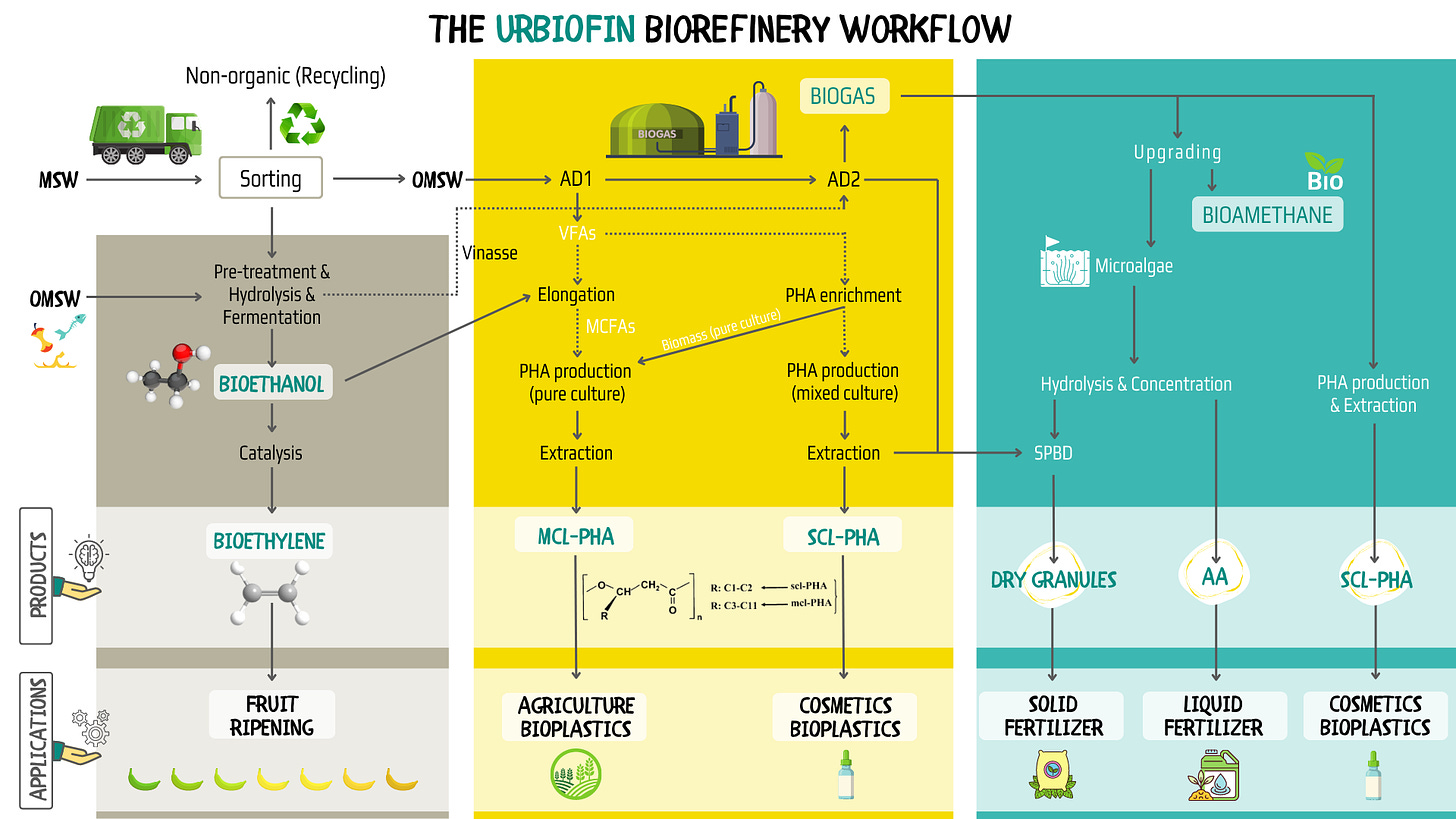

The URBIOFIN project mission was to demonstrate the techno-economic and environmental viability of an integrated biorefinery. The URBIOFIN solution comprises modular and inter-related technologies for the transformation of the organic fraction of municipal solid waste into chemical building blocks such as bioethanol, biogas, volatile fatty acids and medium-chain fatty acids, and into high added-value products such as bioethylene, bioplastics and biofertilisers.

From urban waste to bioproducts through biorefinery

The transformation of the organic fraction of municipal solid waste into advanced bioethanol took place in PERSEOBiotechnology demo plant in Valencia, Spain. The technology was developed by PERSEO, in collaboration with CIEMAT, NOVOZYMES and IRIS.

Followingly, the fermentation byproduct (vinasse) was moved to URBASER anaerobic digestion system, while the produced bioethanol was catalytically converted into bioethylene for agronomic purposes, a process led by CSIC.

URBASER used a 2-phase-anaerobic digestion technology to produce fatty acids, solid digestate and biogas from the biowaste at their demo site. The biogas produced was then purified, while the fatty acids were transported to the Biorefinery Pilot Plant of CLAMBER. At CLAMBER, volatile fatty acids were converted to medium-chain fatty acids through fermentation, and short-chain length or medium-chain length polyhydroxyalkanoates via bacterial accumulation. These polyhydroxyalkanoates were then chemically extracted from the bacteria for further processing and use in packaging applications. CLAMBER led these activities in cooperation with WUR and AINIA.

The biogas and the solid digestate already produced at URBASER facilities were transformed to short-chain length polyhydroxyalkanoates and solid fertilisers, respectively. Also, biogas was upgraded to biomethane using microalgae and bacterial biofiltration technologies. The microalgae biomass was sequentially harvested for the production of aminoacid-rich biostimulants, for agricultural applications. UVa took the lead on these actions, with the support of AINIA and BPe.

The bioproducts of the URBIOFIN biorefinery have been processed and industrially validated by BPe, NATRUE, NATUREPLAST, LEYGATECH and AINIA to their final applications; cosmetic pots, garbage bags, composites, ripening gas, liquid and solid fertilisers.

One month before the end of the project’s journey, URBIOFIN has proudly presented its achievements and contributions to the bio-based economy. The URBIOFIN biorefinery can find applications on existing waste treatment plants either by:

incorporating all designed technologies and offering a viable and holistic solution to municipal waste management or,

adapting some of its technologies to existing waste management plants as it compiles several innovative technologies that can meet multiple management needs.

For more details, please visit: https://www.urbiofin.eu.